Despite seeing more digital solutions and services being offered today, which doesn’t require complex shipment routes or need to carry costly inventories. Most businesses today still produce or offer services, that require a physical distribution network towards customers and suppliers.

As any other business process,it should be aligned with the entire value chain, have transparent costs along with an optimized transportation and inventory structure.

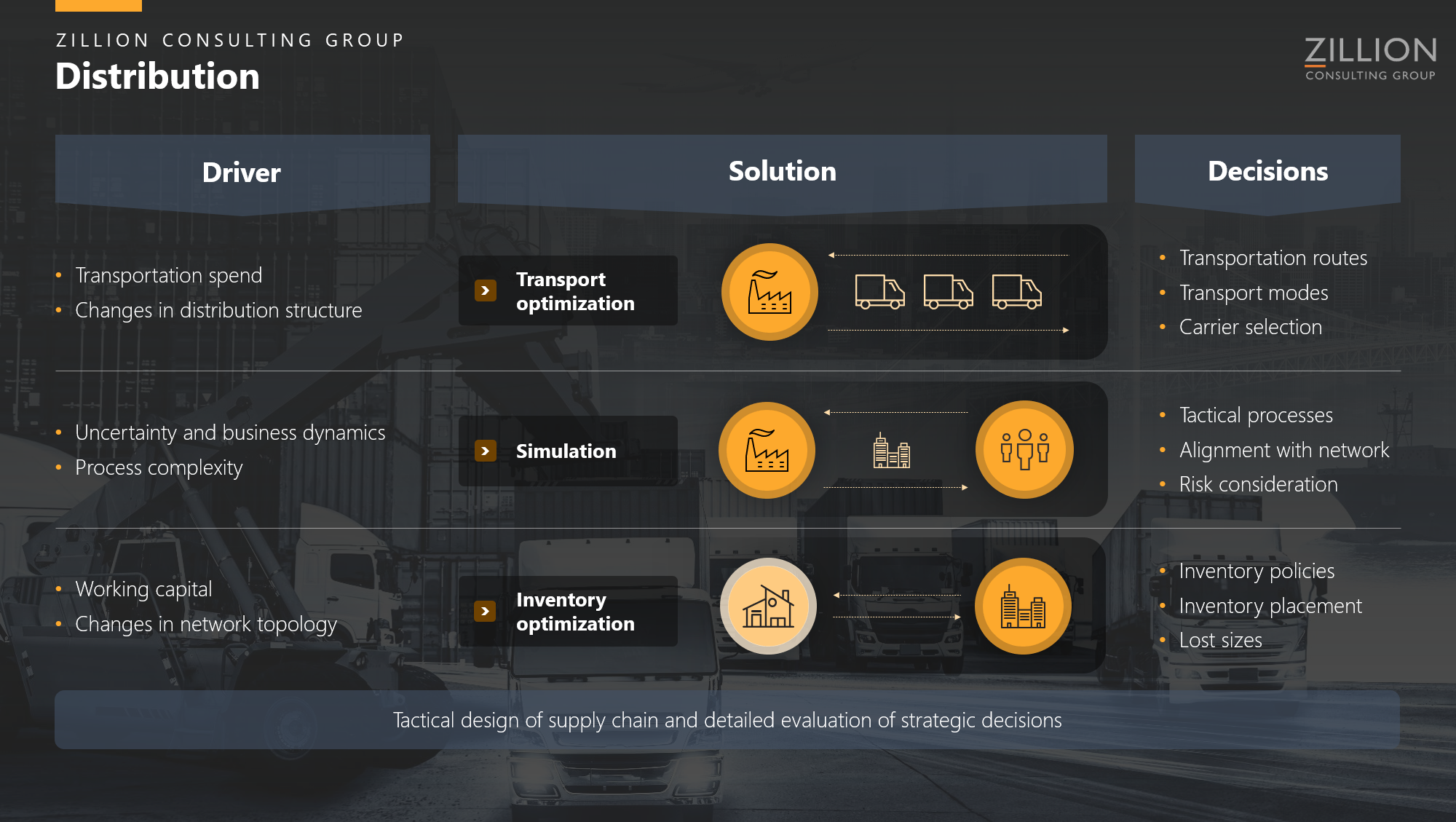

These tasks are crucial if you want to improve the end-to-end processes, which by covering three key areas: Transport optimization, Simulation and Inventory optimization can be achieved.

If optimization is to occur, an analysis of the current state needs to be performed, which seeks to create insights for total cost and map distribution structure and network. Having a point of reference is required to run evaluations on ideas&improvements, both quantitative and qualitative.

The next steps are focused on finding solutions that fit the desired structure and are there strategic or tactical requirements to be considered. These steps could involve consolidation of shipments, routings, balancing of shipments and costs, however it will be based on the initial drivers and uncovered requirements for the business. Therefore, the solutions can be many or few, complex or simple.

Having the distribution structure covered, then the goods being transported needs review as well. As inventories tend to build up for the transports to be filled, it can be a capital intensive and expensive operation.However, with smarter inventories that seeks to decrease carrying costs, working capital and eyes the customers satisfaction from the beginning.The results aim to reduce total costs of transportation, reduce inventory risk and improve on cash flow and profitability.

To address the complexity and uncertainty from distribution networks, and specifically when changing these networks and policies. A simulation that encompasses all the relevant elements is to be conducted, which will highlight possible risks and errors within the network. It also provides further knowledge to align, decide and develop the solutions, which is significantly less costly than implementing solutions that doesn’t work or fulfill requirements.

Typical deliveries in a Distribution process with ZCG:

- Full transparency of total transportation costs.

- Gravity modelling with balance to unit costs and inventories.

- How to consolidate shipments and build multi-stop routes?

- Should we ship direct from vendor or go through DC’s.

- How much savings could be obtained by optimizing existing routes?

- How would routes and modes change with low, average, and high shipment volumes?

- How do current route costs compare to LTL and parcel costs?

- How to balance my shipments on weekly schedules?

- How to balance my facility/unit costs with transportation costs?

- The choice and dynamic consolidation of carriers.

- Negotiations with carriers.

- Data integration of network.