To stay competitive in any business environment today, then it’s critical to also stay in control of both customer- and process requirements.

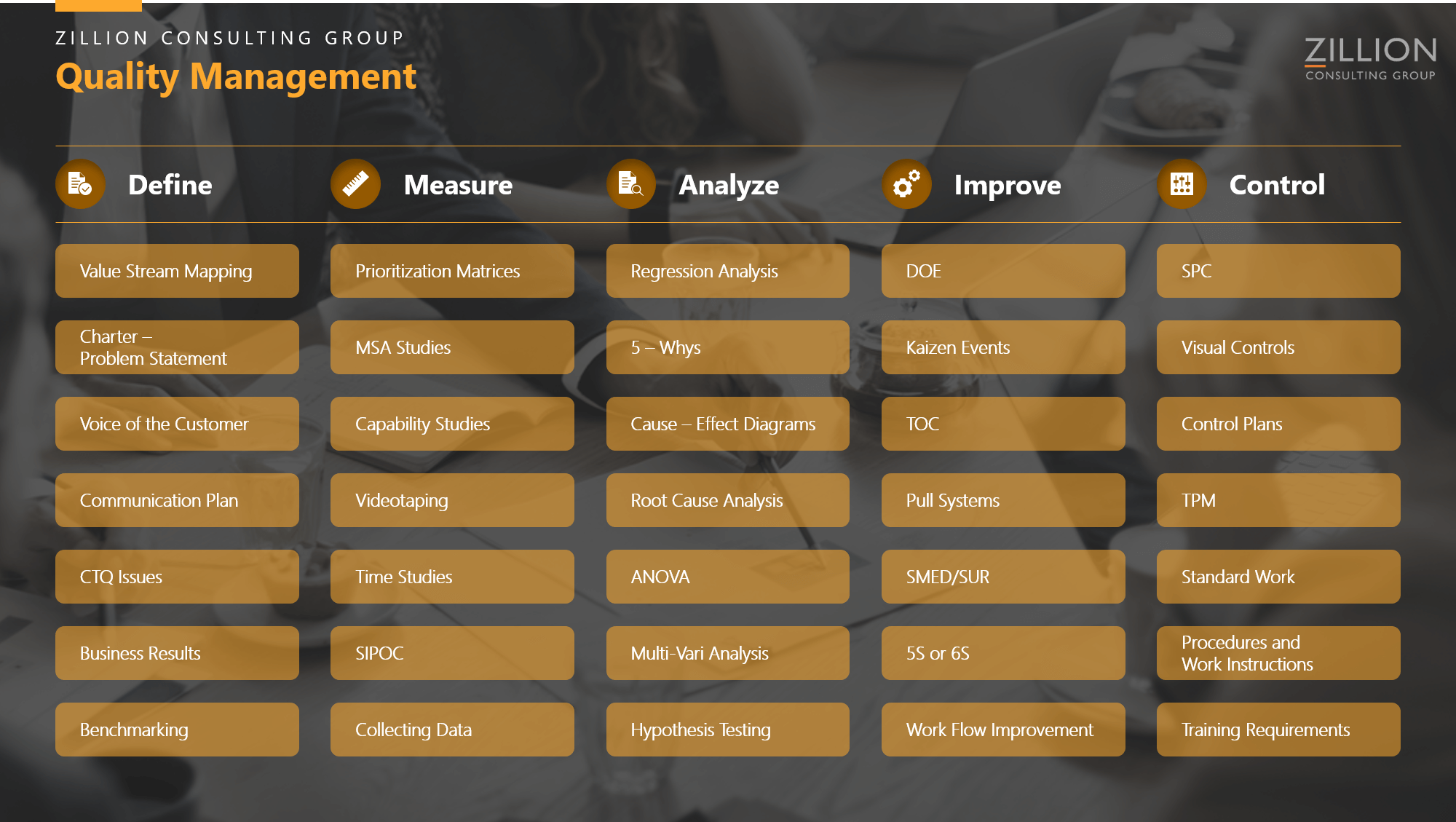

Quality management combines the voice of customers with tools that defines processes and shapes them to stay within limits, so that businesses can stay competitive when the serve their customers.

Customer perceived quality is by now well known to be a leading indicator for success of any business and with the help of tools such as voices of customers it reveals these important indicators.

Performance measures rooted in manufacturing processes such as scrap rates, maintenance costs and first pass yield rates are part of the performance-oriented quality management view.

It quantifies and highlights processes that operates with gaps between demand requirements and actual capabilities, which can then be targeted for improvement.

The idea of analyzing processes for variation gaps needs to be accepted and understood by management as the process orientation isn’t just a tool, but a mindset to be in and make decisions on.

Furthermore, it focuses on processes standardization to reduce variation and improve on documentation for further analysis and compliance within unique certifications such as ISO, ASME, IATF mm.

These clarifications and orientations enable the definition of required skills and flexibility, which are essential when designing processes to these new requirements.

To make initiatives more actionable, tools such as Balanced score card can be implemented as it seeks to reduce the complexity between strategy and operations while being very focused on targets to be achieved. It can enable thematic initiatives, such as “Kill variation”, “Improve lead time” or “Reduce maintenance cost”.

Typical deliveries in a quality management process with ZCG:

- Map of quality voices of the customers.

- Total quality cost overview.

- Quality certificate compliant & process overview. Incl. ISO, ASME, IATF, etc.

- Performance definition by complaint level, first pass yield, scrap rate, and maintenance costs.

- Process orientation of leadership.

- Quantified variation gaps between demand and capability.

- Performance oriented quality management.

- Process standards & documentation.

- Skills and flexibility definitions.

- “Kill variation” initiatives prioritized to total performance.

- Actionable initiatives.